Table Of Content

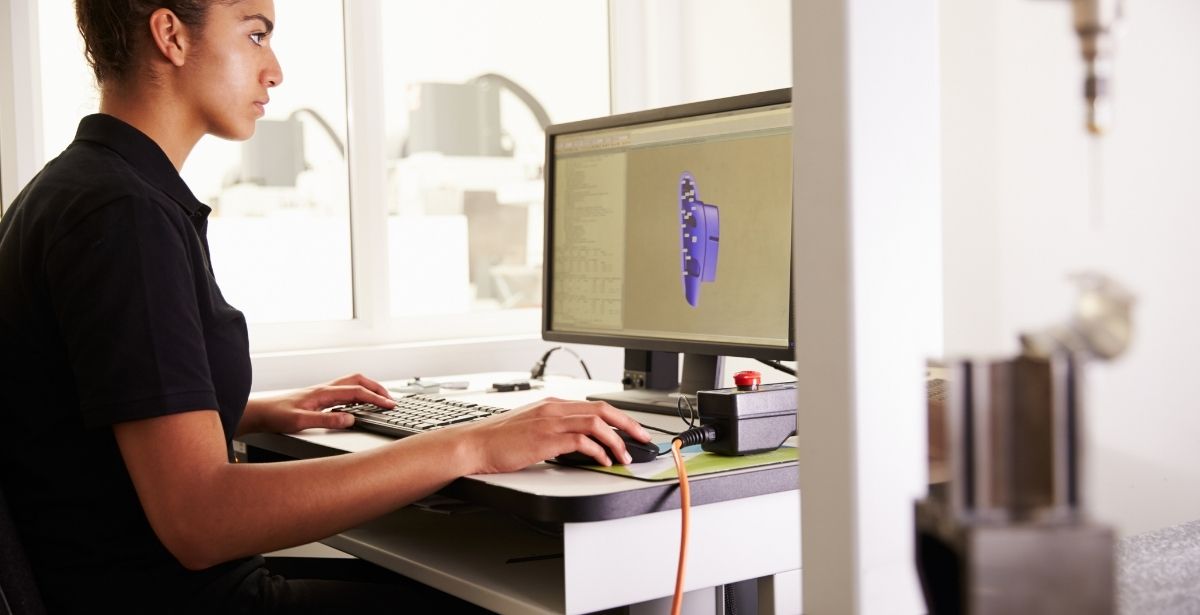

CAD software is used in a wide range of technology firms because it saves a lot of time and resources. Before the development and commercialization of CAD, draftsmen were only able to express their work physically on paper. CAD programs enable the draftsmen to make accurate drawings in a short time with fewer mistakes. In short, we use CAD because it allows us to create detailed and precise visual representations of user interfaces, and because it provides a range of tools and features that can support the design process. Figma is a popular CAD program that’s well known for its collaborative features. It allows multiple designers to work on the same project at the same time and it includes a range of tools and features for creating wireframes, mockups and prototypes.

CAD software classes

In CAD programs, you can make free curves and abstract lines that would require several commands to achieve. Most of these tablets are equipped with customizable buttons for the user to assign functions, and a rechargeable pen for drawing. Easier to understand – 3D models can be much easier to understand and comprehend than complex physical sketches. This also means that CAD models can be used in marketing and sales pitches to clients as they look impressive and clearly demonstrate the aesthetics and functions of a design. Collaboration – Many designers work as part of a team, so collaboration is key. Many CAD programs now use cloud technology, so that designs are accessible at all times and don’t even need to be manually shared.

Best CAD Software 2023 (For Every Skill Level!)

This indicates that the characteristics and relationships we feed into geometry, shape and size are controlled. If you use solid geometric modeling, which requires that you apply material first, the geometric will respond to forces similarly to real objects. A standard CAD system requires the installation of a CAD software package and, occasionally, a graphics card on your computer to work. The graphical user interface (GUI) is another crucial component of CAD software. The first commercial numerical-control programming system, PRONTO, created by Dr. Patrick J. Hanratty in 1957, is credited with giving rise to computer-aided design (CAD).

The Role of Humans in AI Software Testing: It’s Bigger Than You Think

Great for those who aren’t bothered with mastering modeling but want the benefits of printing. The software makes it considerably quicker than hand drawing to produce a mockup of any physical place in a 2D or 3D model. The majority will begin with a 2D layout as they collaborate with a customer to plan the overall positioning of important furniture or fixtures. The software can create parts with the highest precision, including veneers, prostheses, and crowns for dental implants. The treatment may be planned using CAD software, and the custom-made piece can be manufactured without removing the mouth molds.

Yes, numerous educational institutions and software companies offer CAD certificate programs. These programs typically cover fundamental concepts, software tools, and real-world applications of CAD. Certifications can demonstrate a level of competency and professionalism in computer-aided design and are often favored by employers. Moreover, computer-aided design supports the creation of accurate digital prototypes that mimic real-world objects, including the smallest details of their form and geometry. By simulating the cutting process, machinists can identify potential issues, optimize designs, and eliminate costly mistakes. For 3D CAD design, Blender has a deep range of CAD modeling, sculpting, curving, and rendering features to help you create stunning 3D models.

Documentation – CAD software documents every part of the design process, including measurements, angles and dimensions. These properties can be easily reused in future projects, and you can also easily save components and subassemblies for futures designs. For example, CAD software is used by architects to create floor plans of buildings and houses, and these floor plans contain most of the information that would be needed to construct the inside of the building.

Computer Components

Top 10: The Best Free CAD Software in 2024 - All3DP

Top 10: The Best Free CAD Software in 2024.

Posted: Wed, 24 Jan 2024 08:00:00 GMT [source]

In 1936, Alan Turing described what would later be dubbed the “Turing Machine,” which are computational machines intended to analyze the limitations of what can be computed and were designed to process real numbers. There are several different types of CAD,[9] each requiring the operator to think differently about how to use them and design their virtual components in a different manner. Virtually all of CAD tools rely on constraint concepts that are used to define geometric or non-geometric elements of a model.

Improved computational power and algorithms in the eighties made it possible to incorporate a third dimension into the basic 2D CAD programs and birthed three dimensional or 3D CAD. The 3D CAD systems include the dimension of depth or height in technical drawings enabling the designers to create life-like models of their projects and spin them around to display different angles and views. CAD Plant 3D makes offers modern 3D design solutions for plant designers and engineers. The program helps simplify the modeling of plant components, including piping and support structures. The software offers a number of tools to deal with typical plant and process design challenges, such as the standardization and customization of parts for a particular project. It also improves accuracy as well as increases design and engineering productivity as typical challenges are addressed when building the model.

NX CAM

The history of computer-aided design dates back to the 1960s when engineers used it as a drafting tool. Back then, CAD systems were high-speed, standalone mainframes that were not user-friendly and were only used for very specific applications. CAD software can also facilitate the flow from the design process to the manufacturing process. This software can simulate the movement of a part through the manufacturing process in three dimensions.

This is because of the practical experience offered in a CAD certificate program. In Goodwin’s training program, for example, students gain hands-on practice, designing 2-dimensional and 3-dimensional parts using industry software like Solidworks, Mastercam, and PC-DMIS. Students develop detailed design and drawing skills, produce blueprints, and learn about the functional relationships between components, assemblies, systems, and machines—all in a matter of months.

As this occurs, more people and businesses will begin utilizing CAD software to design parts for 3D printing. Because of its versatility, CAD technology has many applications and is often utilized differently depending on the professional. The best way to incorporate CAD technology into your job will vary depending on your industry. Learn about the benefits of computer-aided design (CAD) technology, the industries where it’s utilized, and emerging trends in the area. Discover thought leadership to inspire leaders in architecture, construction, manufacturing, engineering and design.

Before computer software and CAD, designers and engineers had to draw their designs on paper to create new products manually. This naturally had its problems — it was much slower, more prone to human error, and less repeatable. Computer-aided design (CAD) is a crucial field in product engineering and the industrial sector. It allows engineers to develop, test, and optimize their design in a safe environment, without having to build expensive prototypes. CAD software also provides a documentation trail, records specifications, and enables collaboration between multiple disciplines and stakeholders in product manufacturing. That is why organizations need to understand how computer-aided design works and its key concepts.

3D CAD systems initially only modeled arcs and lines and were referred to as 3D Wire-frame Models. They presented a skeletal representation of the finished product and displayed all internal components of the system. Graphics tablets are flat touch-sensitive panels that you connect to your computer via a USB port. People really like the wireless versions because they give you the freedom to move around. The tablets are fashioned to let the user make drawings freely without the limitations of a mouse. The one that’s best for a particular project will depend on your project’s requirements and specifications.

Experience the flexibility of accessing AutoCAD’s key design features from any computer or mobile device. Automate counting blocks, incorporate changes, display measurements, and more. Ready to see how computer-aided design can transform how your team collaborates and brings products to life? While it offers some distinct advantages, 3D may not be the optimal design method for you. When selecting a medium for your design, it’s critical to carefully consider your needs and objectives before making a final decision.

Older versions of software are often cheaper and contain lower system requirements. 2D CAD software often has low system requirements when compared to 3D CAD systems. Further, as a beginner, it may be good to focus on and master the 2D system before moving on to the three-dimensional programs.

All in all, at the fundamental level, CAD software can either be two dimensional (2D CAD) or three dimensional (3D CAD). Your choice of CAD program will depend on your budget, what you want to use it for, and your personal preferences. For example, architects and electrical engineers may end up using different CAD software simply because of the kind of drawings they want to make.

No comments:

Post a Comment